All Language Post

Metallurgical and metal working processes

Forge – punches, screw drivers, chisels, grind them to shape and heat treat to requirement, bending metals to angles, curves & twisting, Preparation of brackets.

Metallurgical and metal working processes such as Heat treatment, various heat treatment methods -normalizing, annealing, hardening, case hardening and tempering. Power hammer – construction, features, method of operating and uses.

- Fitter

Fitter [Duration: 2 years, NSQF level-5]

Course Content :

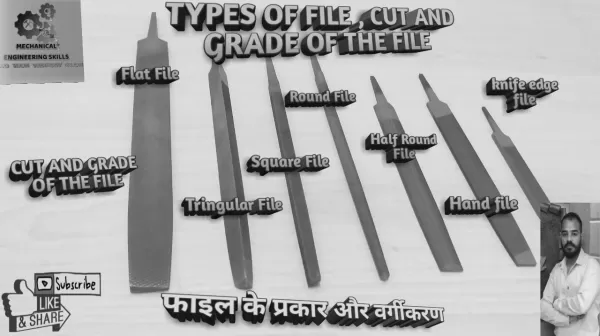

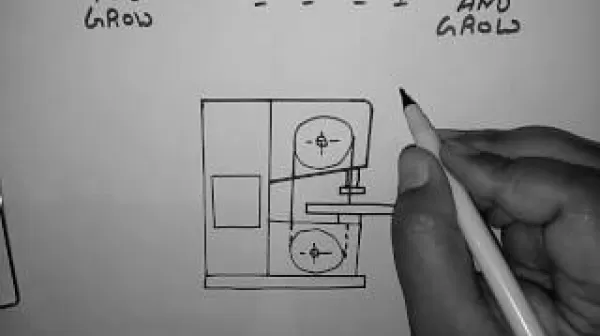

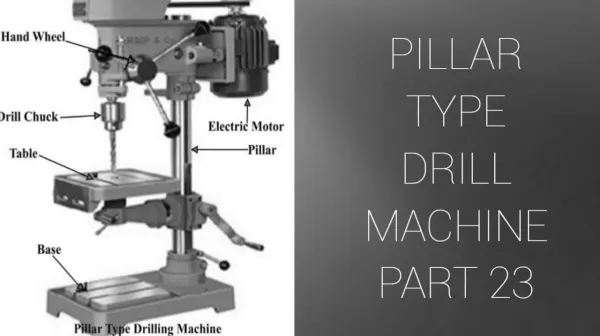

FIRST YEAR: The practical part starts with basic fitting in the beginning and the candidate also imparted training on allied trades viz., Sheet Metal, Welding (Gas & Arc) which leads to multiskilling. In the basic fitting the skills imparted are sawing, filing, marking, chipping, measurement, riveting, soldering, brazing, drilling and observation of all safety aspects is mandatory. The accuracy achieved is of±0.25 mm. The safety aspects cover components like OSH & E, PPE, Fire extinguisher, First Aid and in addition 5S being taught.Different drilling operations (through, blind, angular), reaming, offhand grinding, tapping, dieing, different fits viz., sliding fit, etc., scraping, fastening (nuts & bolts, riveting, studs, screws, etc.,). The accuracy achieved is of± 0.04 mm and angular accuracy to 30minutes.Different turning operations on lathe (step, grooving, chamfering, drilling, boring, knurling &threading), simple repair, overhauling and lubrication work on machine are being taught in the practical.

SECOND YEAR: Power tool operation, different complex assembling and fitting, fastening, lapping, making gauges, pipe works and pipe joints, dismantling, overhauling& assembling valves are covered. The accuracy achieved is of an accuracy of ± 0.02 mm & 10 minutes. Making & using drill jigs, making of critical components, repair & maintenance of power transmission system, making of template &complex gauges, identify different Pneumatic &hydraulic components and circuit construction, repair & maintenance of machinery like lathe, drill, grinding, bench drilling, Inspection of Machine tools, Accuracy testing of Machine tools and erection of simple machines are being performed as part of practical training. Professional Knowledge subject is simultaneously taught in the same fashion to apply cognitive knowledge while executing task. In addition components like Physical properties of engineering materials, Interchangeability, Method of expressing tolerance as per BIS Fits, different types of iron, properties and uses, special files, honing, Metallurgical and metalworking processes such as Heat treatment, the various coatings used to protect metals, different bearing, working material with finished surface as aluminium, duralumin and stainless steel, topics related to non-ferrous metals, Method of lubrication are also covered under theory part. Total three projects need to be completed by the candidates in a group. In addition to above components the core skills components viz., Workshop calculation &science, Engineering drawing, employability skills are also covered. These core skills are essential skills which are necessary to perform the job in any given situation

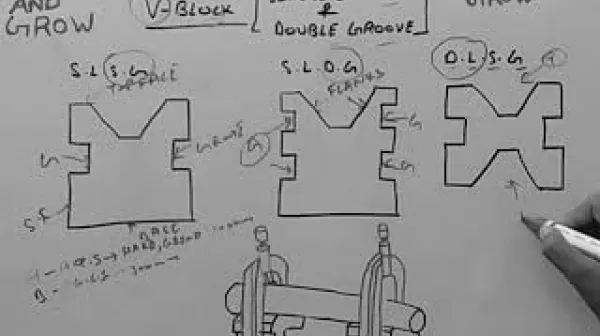

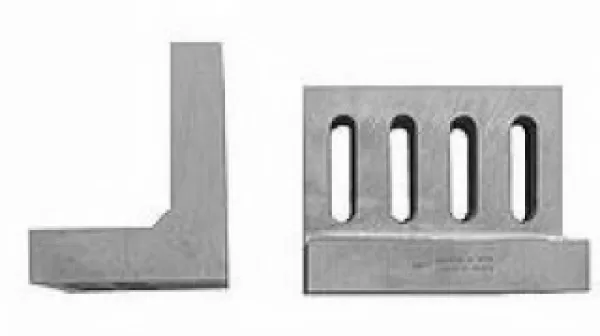

Skills Acquired: Fitter General Sizes metal parts to close tolerances and fits and assembles them using hand tools for production or repairs of machines, or other metal products. Studies drawings to understand specification of different parts, fittings or assembles to be made and their functions. They select materials, appropriate tool and equipments to carry out their work. Holds the work in Vice, Cuts and shapes required parts to dimensions and specifications by processes of sawing, chipping, filing, grinding, drilling holes, screw cutting, scrapping etc., using hand tools for making specimens or finished components. Measures object while working using foot rules, calipers, micrometer, gauges etc. and checks for correct filing with square. Gets half-finished object marked or marks it himself using face plate, marking block scriber, vernier, height gauges, vee-blocks, angle plate, sine plate, slip gauges, combination set, etc. depending on accuracies required, to indicate guide lines for finished sizes, holes to be drilled and pitch centres, threads to be cut and other working details as specified in drawing or sample. Clamps object securely in correct position in vice and files it to required dimensions according to punch marks and guide lines frequently measuring it with calipers, micrometre, vernier, gauges etc, makes holes with drill, cuts threads with taps and dies ensuring that they are square or at required angle to base. Measures finished article with dial indicator, micrometre, vernier, height gauges, screw gauges, plug gauges, sine bar, slip gauge, etc according to prescribed accuracies. May make parts separately and assemble those with screws, rivets, pins, etc. as specified so as to make complete unit according to drawing. Dismantles or removes worn out, broken or defective parts using hand tools or power tools and replaces them by repaired or new ones. Performs repairing and maintenance work (including preventive maintenance) of simple machines, dismantles and replaces different components to construct circuit of Pneumatics and Hydraulics. Tests completed article/ assembly to ensure correct performance. May do simple turning of parts on machines and perform welding, brazing, and like operations. May explain heat treatment processes viz., annealing, hardening, tempering etc. May specialize in particular type of machine or product and be designated accordingly. May suggest alterations. In addition, Fitter have the ability to visualize the job, good coordination, mechanical attitude, manual dexterity and perform work related mathematical calculations. Plan and organize assigned work and detect & resolve issues during execution. Demonstrate possible solutions and agree tasks within the team. Communicate with required clarity and understand technical English. Sensitive to environment, self-learning and productivity.May be designated as FITTER General according to nature of work done.

Options for employment: Bench fitter in manufacturing industries; maintenance fitter in shipping industries and oil rigs; erection in various industries; fabricator for windows/shutter in small workshops; Stores clerk in an Engineering stores.

Options for self-employment / Entrepreneurship Development: Can set up own workshop for fabrication and structural work such as grills, gates, steel; furniture and shutters; can carry out repairs and maintenance of domestic water pipe line individually; can manufacture cutlery such as chopper, knife, axe and chisel; can manufacture and repair locks and keys; can undertake repairs of machines

ITI trade Fitter is powered by NCVT. ITI trade Fitter is a job oriented trade ITI trade Fitter is suitable for government job and private job. This ITI trade Fitter is very powerful for self-empowerment. This ITI trade Fitter is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

Fitters have a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs. On successful completion of this course, the candidates shall be gainfully employed in the following industries:

- Production & Manufacturing industries.

- Structural Fabrication like bridges, Roof structures, Building & construction.

- Automobile and allied industries

- Service industries like road transportation and Railways.

- Ship building and repair

- Infrastructure and defence organizations

- In public sector industries like BHEL, BEML, NTPC, etc and private industries in India & abroad.

- Self employment

International Comparability

- Existence of any official document suggesting the comparability of the qualification with the qualifications in other countries is not known.

- However, ITI passed out trainees are getting employment in many Gulf countries, European countries, Australia, New Zealand, Singapore etc.

Progression Pathway

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education

- Can take admission in diploma course in notified branches of Engineering by lateral entry

- Can join as semi-skilled worker in the industry and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC) after which they will be employed in industry as skilled worker and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after which they will be employed in ITI/ Vocational Training Institute as instructor

Trades Summery:

Fitter is a Mechanical trade in which you can learn about all items related to metal, Machining of a job(Piece of metal) and also get knowledge about measurement and cutting tools - equipment.

After compilation of fitter course you can get job as a technician or machine operator in product manufacturing industries and also in MNC companies. In industries there are wide range of requirement for fitter passout students.

If you are looking for further studies than you can get admission in direct third semester of diploma mechanical branch.

If you are not 12th passout than you can get 12th passed certificate after passing 12th language subject.

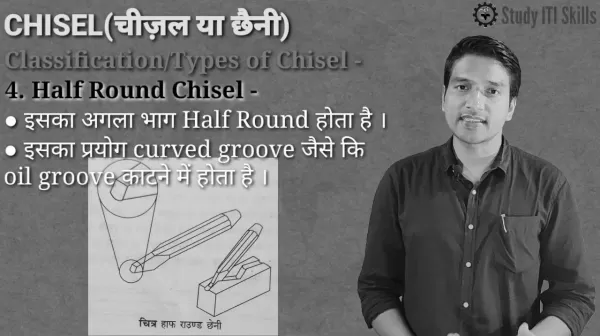

- (i) Plan and organize the work to make job as per specification applying different types of basic fitting operation and Check for dimensional accuracy. [Basic fitting operation – marking, Hacksawing, Chiseling, Filing, Drilling, Taping and Grinding etc. A

- (ii) Manufacture simple sheet metal items as per drawing and join them by soldering, brazing and riveting.

- (iii) Join metal component by arc welding observing standard procedure.

- (iv) Cut and join metal component by gas (oxy-acetylene

- (v) Join metal components by riveting observing standard procedure.

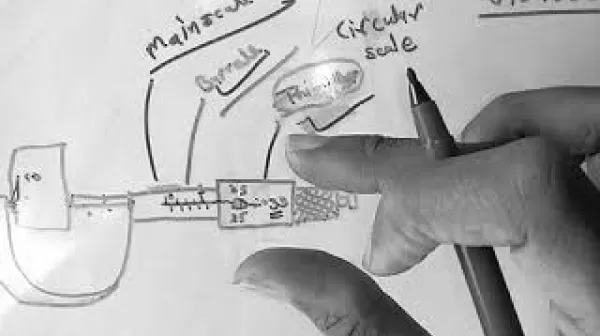

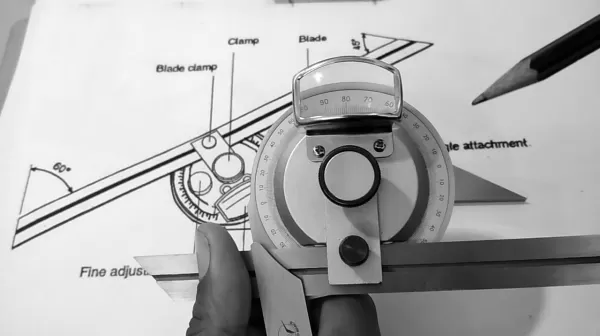

- (vi) Produce components by different operations and check accuracy using appropriate measuring instruments.[Different Operations - Drilling, Reaming, Taping, Dieing; Appropriate Measuring Instrument – Vernier, Screw Gauge, Micrometer]

- (vii) Make different fit of components for assembling as per required tolerance observing principle of interchangeability and check for functionality. [Different Fit – Sliding, Angular, Step fit, ‘T’ fit, Square fit and Profile fit; Required tolerance: ±0

- (viii) Produce components involving different operations on lathe observing standard procedure and check for accuracy. [Different Operations – facing, plain turning, step turning, parting, chamfering, shoulder turn, grooving, knurling, boring, taper turni

- (ix) Plan & perform simple repair, overhauling of different machines and check for functionality. [Different Machines – Drill Machine, Power Saw, Bench Grinder and

- (x) Make & assemble components of different mating surfaces as per required tolerance by different surface finishing operations using different fastening components, tools and check functionality. [ Different Mating Surfaces – Dovetail fitting, Radi

- (xi) Make different gauges by using standard tools & equipment and checks for specified accuracy. [Different Gauges – Snap gauge, Gap gauge; Specified Accuracy - ±0.02mm

- (xii) Apply a range of skills to execute pipe joints, dismantle and assemble valves & fittings with pipes and test for leakages.[Range of skills – Cutting, Threading, Flaring, Bending and Joining ]

- (xiii) Make drill jig & produce components on drill machine by using jigs and check for correctness.

- (xiv) Identify, dismantle, replace and assemble different pneumatics and hydraulics components. [Different components – Compressor, Pressure Gauge, Filter Regulator Lubricator, Valves and Actuators.]

- (xv) Construct circuit of pneumatics and hydraulics observing standard operating procedure& safety aspect.

- (xvi) Plan, dismantle, repair and assemble different damaged mechanical components used for power transmission & check functionality. [Different Damage Mechanical Components – Pulley, Gear, Keys, Jibs and Shafts.]

- (xvii) Plan, erect simple machine and test machine tool accuracy. [Simple Machines – Drill Machine, Power Saw and Lathe]

- (xviii) Recognize & comply safe working practices, environment regulation and housekeeping

- (xix) Understand and explain different mathematical calculation & science in the field of study including basic electrical. [Different mathematical calculation & science -Work, Power & Energy, Algebra, Geometry & Mensuration, Trigonometry, Heat & Temperat

- (xx) Interpret specifications, different engineering drawing and apply for different application in the field of work. [Different engineering drawing-Geometrical construction, Dimensioning, Layout, Method of representation, Symbol, scales, Different Proje

- (xxi) Select and ascertain measuring instrument and measure dimension of components and record data.

- (xxii) Explain the concept in productivity, quality tools, and labour welfare legislation and apply such in day to day work to improve productivity & quality.

- (xxiii) Explain energy conservation, global warming and pollution and contribute in day to day work by optimally using available resources.

- (xxiv) Explain personnel finance, entrepreneurship and manage/organize related task in day to day work for personal & societal growth

- (xxv) Plan and organize the work related to the occupation

Free Download pdf