Machinist

Machinist [Duration: 2 years, NSQF level-5]:

Course Content:

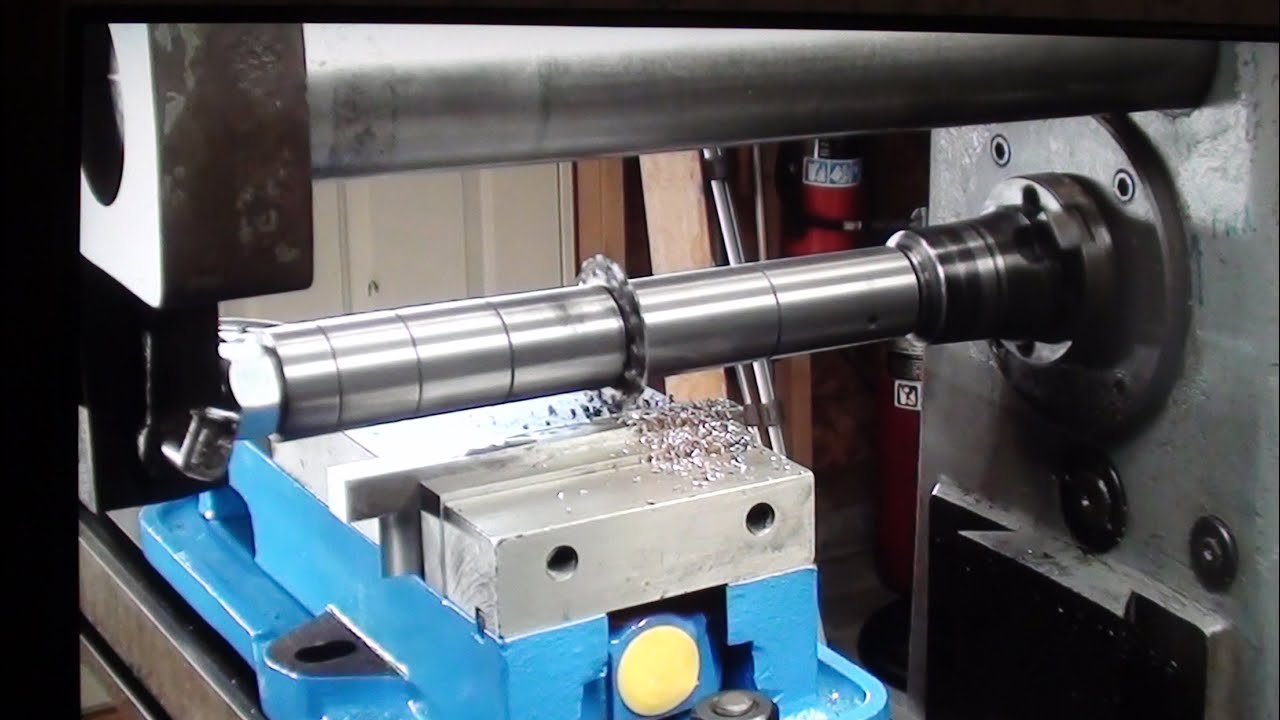

FIRST YEAR – In this year, the contents covered are from safety aspect related to the trade, basic fitting operations viz., making, filing, sawing, chiseling, drilling, tapping, grinding to an accuracy of±0.25mm. Making different fits viz., sliding, T-fit and square fit with an accuracy of ±0.2mm &angular tolerance of 1. Lathe operation on different shaped job and produce components by different turning operation including thread cutting. The practical training starts with operation of slotting machine and making different components to accuracy of ±0.04 mm. Followed by different operation in conventional milling machine with extensive coverage of different operations viz., plain, face, angular, form, gauge, straddle milling with accuracy ±0.02 mm like square thread cutting. Further advance turning operations with accuracy ±0.04 mm is covered. Next, the grinding operation (both surface andcylindrical) is executed with accuracy of ±0.01mm.

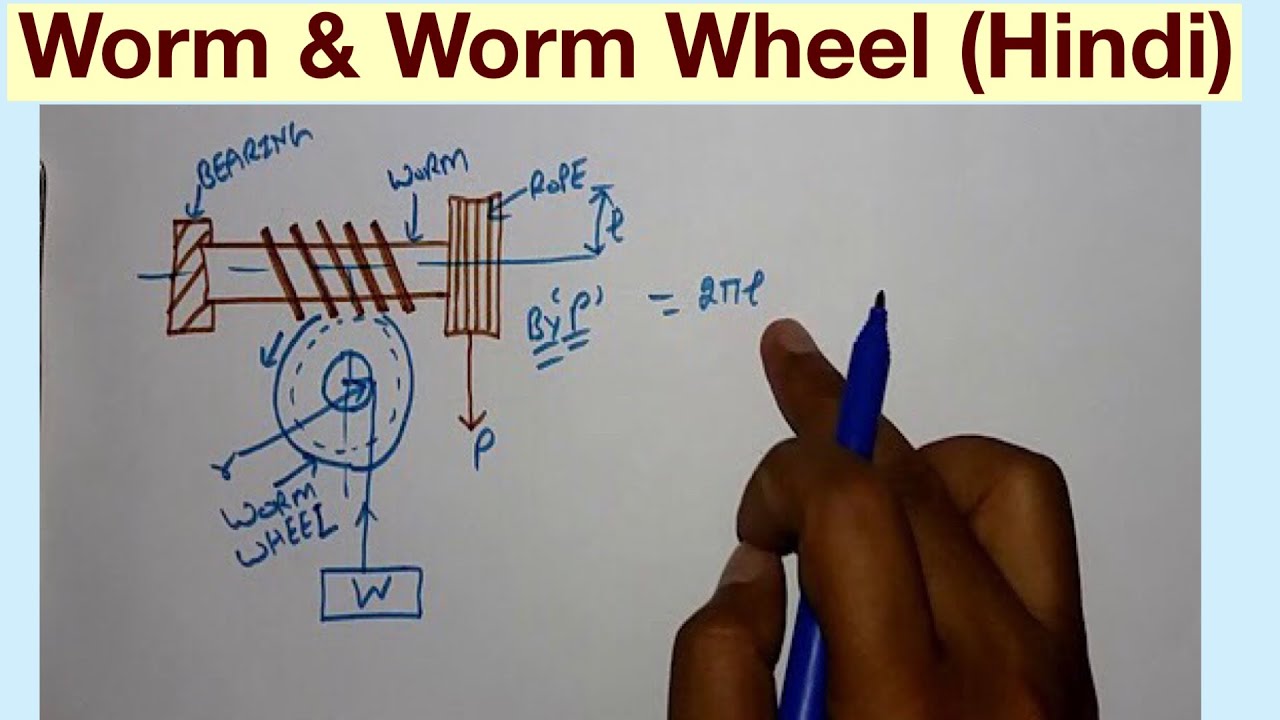

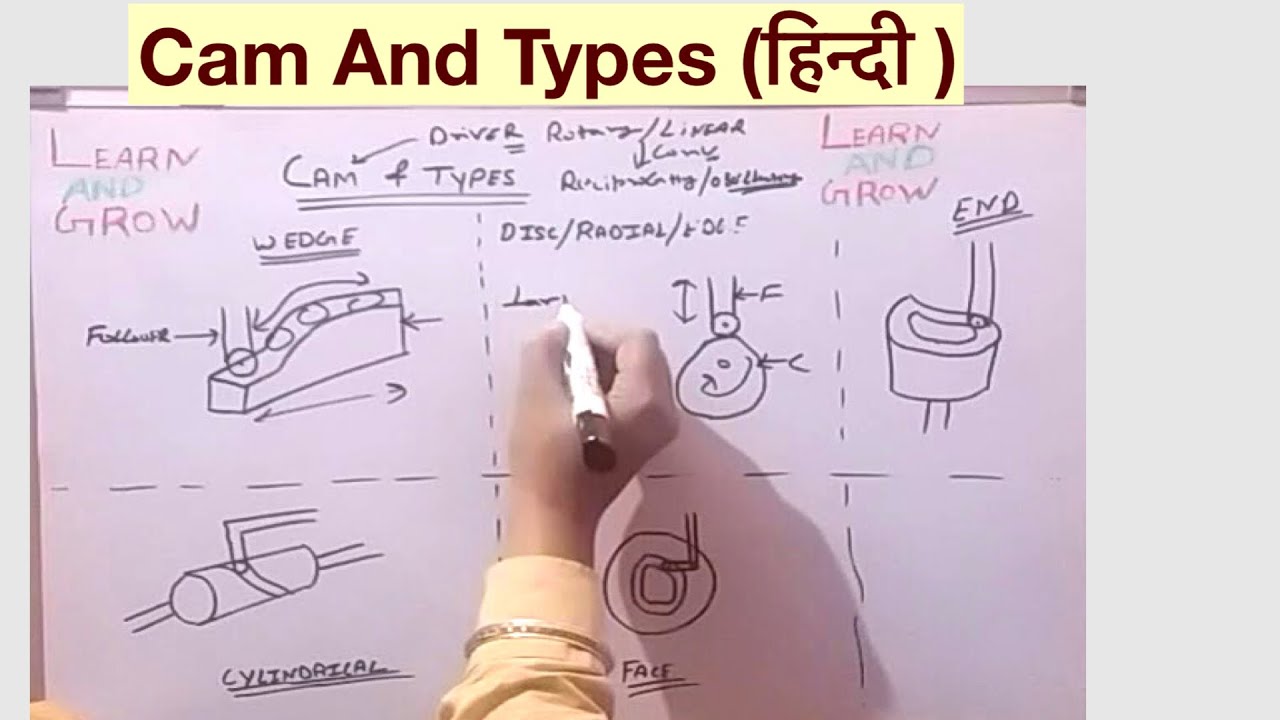

SECOND YEAR -In this year, grinding of different cutting tools are covered in the beginning followed by advance milling operation like boring, gear cutting, spline etc. to accuracy ±0.05mm.Basic electrical equipment and sensors are also covered and CNC turning operation which covers staring from setting, operation and programming part covered for producing different components. The CNC milling operation is covered in the beginning which include setting, operation and part programming to producing different component. In addition to this, the components like documentation, technical English, simple repair and maintenance work, machining of some complicated components like bevel gears, plate components, worm wheel, worm thread etc. toan accuracy of ±0.05mm.In addition to above components the core skills components viz., Workshop calculation & science, Engineering drawing, employability skills are also covered. These core skills are essential skills which are necessary to perform the job in any given situation.

Skills Acquired: Machinist General operates various types of power driven metal cutting or grinding machines for cutting and grinding metal. Studies drawings or measures out sample with appropriate measuring instruments to note different dimensions and sequence of operations required. Selects metal piece and marks it or gets it marked for machining operations required. Fastens metal in chuck, jig or other fixture and respective tool or cutter, according to sequence of operation, on appropriate machine (lathe, shaper, milling, slotting, drilling, grinding).Checks machine setting or sets it for stipulated machine operations. Selects machine feed and speed and starts machine. Controls flow of coolant (cutting lubricant) and manipulates hand wheels or applies automatic controls to feed tool to metal or metal to tool. Observes cutting or grinding both from marking and machine readings, checks for dimensions as necessary and removes parts when machining is completed, checks completed part with measuring instruments and gauges to ensure prescribed accuracy. Makes adjustments if necessary and repeats operations, as required, on same or other machines. May assist in setting up machine for repetitive work, change tools, make simple adjustments, clean and oil machine. Does process planning, tool and cutting parameters selection, programming, setup and operation for cutting parts on CNC vertical machining center and CNC lathe. Plan and organize assigned work, detect & resolve issues during execution. Demonstrate possible solutions and agree tasks within the team. Communicate with required clarity and understand technical English. Sensitive to environment, self-learning and productivity. May be designated as Machinist according to nature of work done.

Options for employment: There is lot of demand for machinist in major industries like Goa Shipyard, Mormugao Port Trust, A.C.G.L., GAAL and also various small scale industries which exist in various industrial estates.

Options for self-employment / Entrepreneurship Development: Skilled Machinist can start his own workshop and can supply the products of various jobs to the auxiliary units as a sub-contractor.

ITI trade Machinist is powered by NCVT. ITI trade Machinist is a job oriented trade ITI trade Machinist is suitable for government job and private job. This ITI trade Machinist is very powerful for self-empowerment. This ITI trade Machinist is perfectly design to fulfill industrial requirement of Indian Industries as well as International industries.

On successful completion of this course, the candidates shall be gainfully employed as:

• Machinist, Grinder, Operator of various types of power driven metal cutting or grinding machines in Production & Manufacturing industries,Infrastructure and defence organizations.

• Machinists have a wide scope of Employability ranging from self-employment, contractual employment to Industrial jobs.

International Comparability

- 1. Comparison Made with German Syllabus and the proposed syllabus is in line with the existing German Syllabus (Around 95% contents are matching).

- 2. However, ITI passed out trainees are getting employment in many Gulf countries, European countries, Australia, New Zealand, Singapore etc.

Progression Pathway

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education

- Can take admission in diploma course in notified branches of Engineering by lateral entry

- Can become supervisor after doing part-time diploma in relevant branch of Engineering.

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC) after which they will be employed in industry as skilled worker and can become supervisor after doing part-time diploma in relevant branch of Engineering

- Can join Crafts Instructor Training Scheme (CITS) in the relevant trade after which they will be employed in ITI/ Vocational Training Institute as instructor

Trades Summery:

Semester – I

- (i) Plan and organize the work to make job as per specification applying different types of basic fitting operation and Check for dimensional accuracy. [Basic fitting operation – marking, Hacksawing, Chiselling, Filing, Drilling, Taping and G

- Produce components by different operations and check accuracy using appropriate measuring instruments.[Different Operations - Drilling, Reaming, Tapping, Dieing; Appropriate Measuring Instrument – Vernier, Screw Gauge, Micrometer]

- Make different fit of components for assembling as per required tolerance observing principle of interchange ability and check for functionality. [Different Fit – Sliding, Angular, Step fit, ‘T’ fit, Square fit and Profile fit; Required tolerance: ±0.2 mm

- Set different shaped jobs on different chuck and demonstrate conventional lathe machine operation observing standard operation practice. [Different chucks: 3 jaws & 4 jaws, different shaped jobs: round, square, hexagonal]

- Prepare different cutting tool to produce jobs to appropriate accuracy by performing different turning operations. [Different cutting tool – V tool, side cutting, parting, thread cutting (both LH & RH), Appropriate accuracy: - ±0.06mm, Different turning o

- Set different components of machine & parameters to produce taper/ angular components and ensure proper assembly of the components. [Different component of machine: Form tool, Compound slide, tail stock offset; Different machine parameters- Feed, speed, d

- Set the different machining parameters to produce metric-v threaded components applying method/ technique and test for proper assembly of the components.

Semester – II

- Set the different machining parameters and cutting tool to prepare job by performing different slotting operation. [Different machining parameters – feed, speed and depth of cut. Different slotting operations–concave & convex surface, internal key ways, p

- Set the different machining parameters and cutters to prepare job by performing different milling operation and indexing. [Different machining parameters – feed, speed and depth of cut. Different milling operations – plain, face, angular, form, gang, stra

- Set the different machining parameters to produce square & “V’’ threaded components applying method/ technique and test for proper assembly of the components.

- Produce components of high accuracy by different operations using grinding. [Different operations – surface grinding, cylindrical grinding with an accuracy of+/- 0.01 mm]

Semester – III

- Resharpen different single & multipoint cutting tool. [Different single point tools, slab milling cutter, side & face milling cutter, end mill cutter and shell end mill cutter.]

- Set different machining parameters and cutters to prepare job by different milling machine operations. [Different machining parameters - feed, speed, depth of cut, different machining operation – facing, drilling, tapping, reaming, counter boring, counter

- Set the different machining parameters and cutters to prepare components by performing different milling operation and indexing. [Different machining parameters – feed, speed and depth of cut. Different components – Rack, Spur Gear, External Spline, Stee

- Identify and explain basic functioning of different electrical equipment, sensors and apply such knowledge in industrial application including basic maintenance work. [Different electrical equipment- multi-meter, transformer, relays, solenoids, motor & ge

- Set (both job and tool) CNC turning centre and produce components as per drawing by preparing part programme.

Semester – IV

- Set (both job and tool) CNC machining centre and produce components as per drawing by preparing part programme.

- Plan and perform simple repair, overhauling of different machines and check for functionality. [Different Machines – Drilling Machine, milling machine and Lathe]

- Set the different machining parameters and cutters to prepare components by performing different milling operation and indexing. [Different machining parameters – feed, speed and depth of cut. Different components – end mill, bevel gear, cam, worm & worm

Generic Learning Outcomes

- Recognize & comply safe working practices, environment regulation and housekeeping.

- Understand and explain different mathematical calculation & science in the field of study including basic electrical. [Different mathematical calculation & science -Work, Power & Energy, Algebra, Geometry & Mensuration, Trigonometry, Heat & Temperature, L

- Interpret specifications, different engineering drawing and apply for different application in the field of work. [Different engineering drawing-Geometrical construction, Dimensioning, Layout, Method of representation, Symbol, scales, Different Projection

- Select and ascertain measuring instrument and measure dimension of components and record data.

- Explain the concept in productivity, quality tools, and labour welfare legislation and apply such in day to day work to improve productivity & quality.

- Explain energy conservation, global warming and pollution and contribute in day to day work by optimally using available resources.

- Explain personnel finance, entrepreneurship and manage/organize related task in day to day work for personal & societal growth

- Plan and organize the work related to the occupation

Machinist

Generic Learning Outcomes : Machinist

- Recognize & comply safe working practices, environment regulation and housekeeping.

- Understand and explain different mathematical calculation & science in the field of study including basic electrical. [Different mathematical calculation & science -Work, Power & Energy, Algebra, Geometry & Mensuration, Trigonometry, Heat & Temperature, L

- Interpret specifications, different engineering drawing and apply for different application in the field of work.